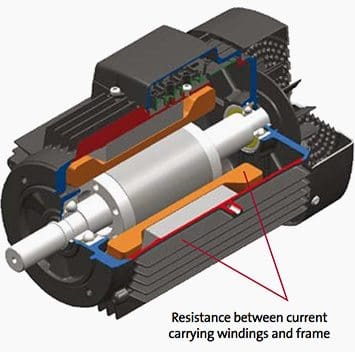

How to measure insulation resistance of a motor (photo credit: elecls.cc.oita-u.ac.jp)

Winding insulation resistance

If the motor is not put into operation immediately upon arrival, it is important to protect it against external factors like moisture, high temperature and impurities in order to avoid damage to the insulation. Before the motor is put into operation after a long period of storage, you have to measure the winding insulation resistance.

It is practically impossible to determine rules for the actual minimum insulation resistance value of a motor because resistance varies according to method of construction, condition of insulation material used, rated voltage, size and type. In fact, it takes many years of experience to determine whether a motor is ready for operation or not.

A general rule-of-thumb is 10 Megohm or more.

| Insulation resistance value | Insulation level |

| 2 Megohm or less | Bad |

| 2-5 Megohm | Critical |

| 5-10 Megohm | Abnormal |

| 10-50 Megohm | Good |

| 50-100 Megohm | Very good |

| 100 Megohm or more | Excellent |

The measurement of insulation resistance is carried out by means of a megohmmeter – high resistance range ohmmeter. This is how the test works: DC voltage of 500 or 1000 V is applied between the windings and the ground of the motor.

Ground insulation test of a motor

During the measurement and immediately afterwards, some of the terminals carry dangerous voltages and MUST NOT BE TOUCHED.

Now, three points are worth mentioning in this connection: Insulation resistance, Measurement and Checking.

1. Insulation resistance

- The minimum insulation resistance of new, cleaned or repaired windings with respect to ground is 10 Megohm or more.

- The minimum insulation resistance, R, is calculated by multiplying the rated voltage Un, with the constant factor 0.5 Megohm/kV.

For example: If the rated voltage is 690 V = 0.69 kV, the minimum insulation resistance is: 0.69 kV x 0.5 Megohm/kV = 0.35 Megohm

2. Measurement

- Minimum insulation resistance of the winding to ground is measured with 500 V DC. The winding temperature should be 25°C ± 15°C.

- Maximum insulation resistance should be measured with 500 V DC with the windings at a operating temperature of 80 – 120°C depending on the motor type and efficiency.

3. Checking

- If the insulation resistance of a new, cleaned or repaired motor that has been stored for some time is less then 10 Mohm, the reason might be that the windings are humid and need to be dried.

- If the motor has been operating for a long period of time, the minimum insulation resistance may drop to a critical level. As long as the measured value does not fall below the calculated value of minimum insulation resistance, the motor can continue to run.

However, if it drops below this limit, the motor has to be stopped immediately, in order to avoid that people get hurt due to the high leakage voltage.

Reference: Grudfos – Motor Book